Iron Casting Manufacturers

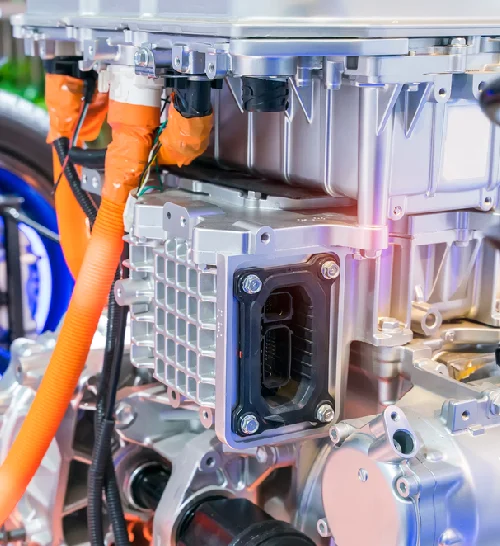

Iron castings have long been integral to the manufacturing industry, known for their exceptional strength, durability, and versatility. As one of the most widely used materials in industrial applications, cast iron offers impressive mechanical properties, including high wear resistance and excellent fluidity, which make it suitable for a wide variety of industries—from automotive and construction to energy and machinery manufacturing.

Types of Iron Castings

Gray Cast Iron: The most common type, known for its excellent castability, machinability, and vibration damping properties. Used extensively in automotive engines, pumps, and machinery components.

Ductile Iron (SG Iron): Also known as nodular iron, this is a more advanced form of cast iron that offers enhanced tensile strength and ductility. Ductile iron castings are used in applications requiring high impact resistance, such as pipe fittings, automotive components, and valves.

White Cast Iron: Known for its hardness and wear resistance, white cast iron is often used in applications requiring durable surfaces such as grinding balls and wear-resistant liners.

Malleable Cast Iron: A more flexible iron alloy with better tensile strength, typically used in products like pipe fittings and electrical components.

Advanced Manufacturing Processes

Leading iron casting manufacturers utilize advanced foundry technologies to produce high-quality components. Some of the most common casting methods include:

- Sand Casting: This traditional technique uses sand molds to produce large, complex castings. It's ideal for low-to-medium production runs and is particularly useful for automotive parts, machinery, and industrial equipment.

- Die Casting: Die casting involves forcing molten iron into molds under high pressure, which allows for high-precision components. It’s widely used for producing small to medium-sized parts that require tight tolerances.

- Investment Casting: For components requiring superior finish and accuracy, investment casting provides exceptional detail and smooth surfaces, making it ideal for aerospace and medical applications.